10 Simple Techniques For Sheroz Earthworks

Table of ContentsSheroz Earthworks Things To Know Before You BuyThe 8-Second Trick For Sheroz EarthworksAn Unbiased View of Sheroz EarthworksAll About Sheroz EarthworksSome Known Details About Sheroz Earthworks

For any type of earthwork contractor, it is crucial to perform collaborate with quality, accuracy, and on time. Using machine control in job equipments makes it possible for maximizing the various stages in the earthwork procedure, from planning to the maintenance stage - trimble parts. The maker control system aids the maker driver in acquiring the target airplane rapidly and easily

The device control system overviews the operator with centimeter precision. Remote assistance conserves time and money, as it lessens downtime in jobsites.

Sheroz Earthworks Things To Know Before You Buy

Our system's components are meticulously developed to endure the rough problems of building and construction sites. Comparison of the exact same task implemented making use of equipment control versus the traditional approach discloses that, on standard, the conventional method requires 50% more time to accomplish the very same task as the technology-assisted method.

Get in the Xsite machine control system; it's below to provide you with a substantial benefit when functioning with earthmoving equipment. Discover exactly how Xsite Maker Control can enhance your productivity and make sure work safety! Xsite Maker Control systems can be set up to any excavator from mini excavators to huge mining excavators.

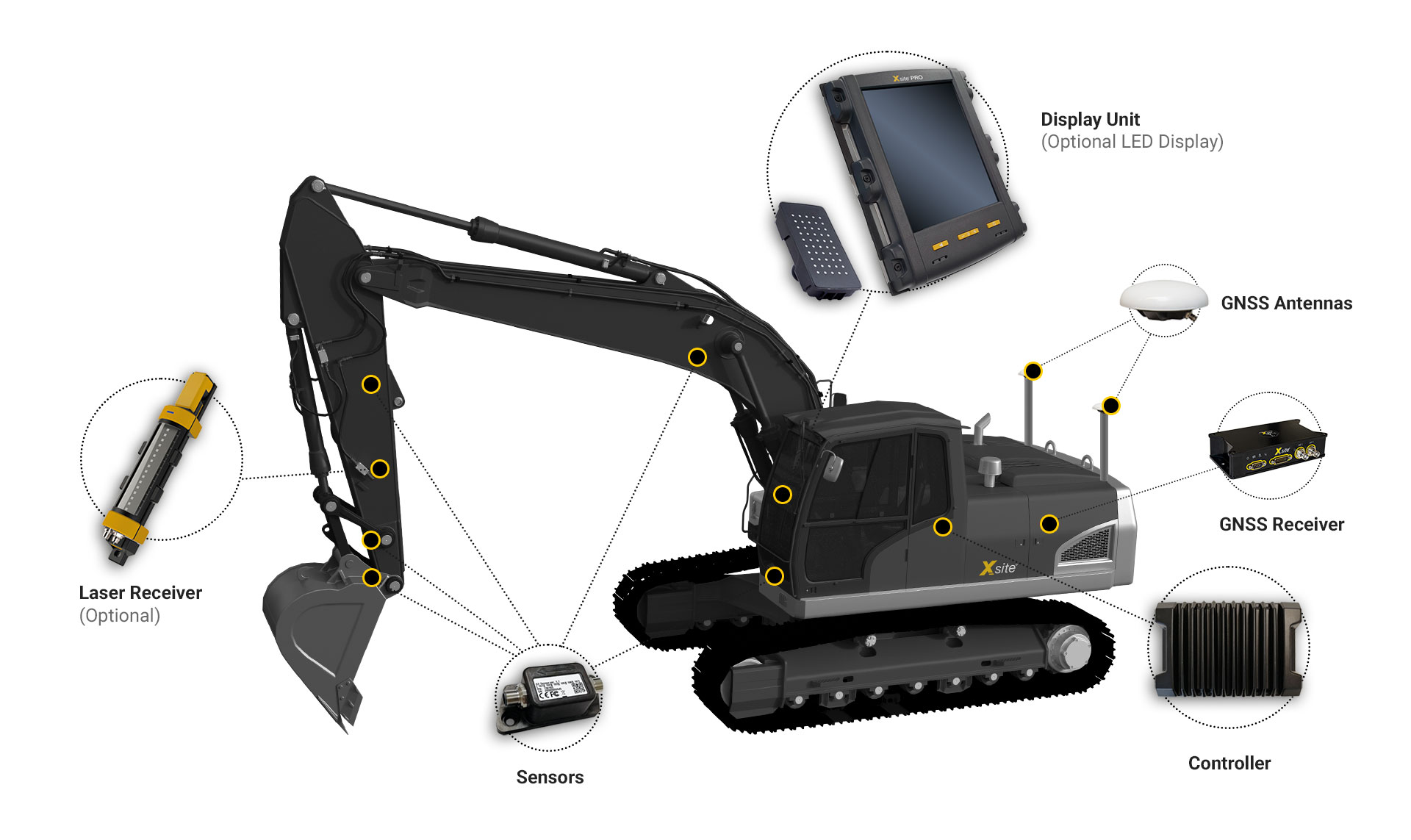

How does equipment control work? In 2D systems, the machine is furnished with adjusted inclination sensors. These sensing units are placed on the pre-determined components of the machine in excavators the sensing unit are typically installed to the framework, boom (or booms), digger arm and to the fast coupler - fj dynamics auto steering kit price. By utilizing the data gotten from these sensing units the system can calculate the exact setting of the excavators container idea in significance to a recommendation point.

The system is very easy to find out the fundamentals can be instructed in under one hour of training. With Xsite you don't have to bother with discovering all the tips and method at once. Added training and guidelines are constantly available over remote assistance when required. Get in touch with your neighborhood Xsite dealer to discover more! How does the remote support work? A wireless net link makes it feasible to establish a remote link between the device control system and the solution.

Some Known Facts About Sheroz Earthworks.

What sort of data styles Xsite systems assistance? Xsite Machine Control systems sustain open common file styles, making it possible for smooth information circulation from one system to one more. Supported file layouts: 2D-Maps: DXF Factor files: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Versions: DXF, XML What elements are installed on my device? Relying on your option of system (with or without placing, i.e - topcon laser levels., 2D or 3D), your maker is equipped with disposition sensors, a controller device, and a display/operating panel.

Several software and hardware options exist to help figure out a maker's present setting on the earth and contrast it with a preferred style surfaceand building drivers can do more to take advantage of the benefits. Maker control is using different placing sensing units and a display to provide the driver with a referral between the position of the bucket or blade and the target grade.

Depending on the setup, maker control systems can provide the driver with an easy aesthetic guide to pail or blade setting, or can immediately relocate the blade to quality by talking to the device's hydraulics - https://www.reddit.com/user/sherozau/. There are maker control systems offered for nearly any type of company website machine: , dozers, excavators, dirt and asphalt compactors, scrapes, trimmers, grating makers, and pavers

What Does Sheroz Earthworks Do?

Some advantages include lowered rework, enhanced task efficiency, and reduced checking expenses. Device control can likewise help enhance efficiency and decrease general expenses. This technology is changing the method the building industry works. Construction equipment without machine control will come to be a distant memory and the advantages obtained from it will certainly be various.

Trimble device control systems provide a myriad of benefits to any individual who uses earthwork machinery and, at EarthCalc, we can give you with 3D files for your maker control-enable devices. Uncertain if machine control is worth the price? Think about the complying with reasons you require to consider this alternative.

Utilizing general practitioner aligned with your 3D layout files, these systems virtually ensure that you will eliminate or put the proper amount of material at the construction website. On many building sites, remodel is an usual and discouraging reality, however with Trimble machine control, you can remove the requirement for rework.

The 25-Second Trick For Sheroz Earthworks

Frequently, with Trimble machine control, you can remove excess devices at a particular task website. A job that could have called for the usage of 3 or 4 pieces of excavating tools now might need just 2 items of devices to accomplish the same task in much less time. This allows you to move your equipment to an additional job site and handle several jobs at one time.